Supply Logistics | Platform Supply & Drilling Support

Learn more about our Vessel Drilling Support, email info@fletcher-group.com

Our systems, procedures, principles and highly skilled workforce have enabled Fletcher to provide a safe and quality service across a spectrum of Offshore Sectors. Establishing our business in the highly regulated Oil and Gas sector has enabled a smooth transition into other Offshore sectors where our skills and experience can be further developed. We have a fleet of carefully chosen young, modern vessels which are purposefully designed to operate in the harsh conditions as required by our customers.

Over the years we have worked alongside most of the oil majors either supporting their Production Platforms, Drilling Operations, Maintenance Shut Downs or hauling pipe for sub-sea pipelines. We have supported these operations in the Northern, Central and Southern Sectors of the North Sea as well as in the harsh conditions of the Atlantic West of Shetland. We have also supported international operations in Denmark and India.

We carry out the normal range of supply vessel duties for clients in the North Sea, either supporting a designated platform, or supporting a 'cluster' of platforms. We are always happy to help our client's source solutions to unusual problems and making the best use of our large deck areas, large underdeck capacity and highly professional crew. Occasionally we have the unique opportunity to assist the coastguard with their winch training exercises, or change-out lifeboats offshore.

Our large deck area is highly desirable for a large number of customer requirements. This is ideally suited for supporting a dedicated drilling operation especially for 'spud' loadouts or for prolonged periods offshore providing 'floating' warehouse storage capability.

With multiple pump capability, we are able to pump heavy muds, brines and dry bulks to heights of 30 metres at a pumping rate of 150 m3 per hour. We are always happy to help our clients source solutions to unusual problems with our highly professional crews.

When it comes to providing specialist services to the offshore maritime sector, we have decades of experience: providing expert advice, helping our Clients deliver a better service, improving efficiency and assisting in making the work-place as safe as possible for the Company, its' clients and staff. Quite simply we deliver proven, cost-effective solutions that work.

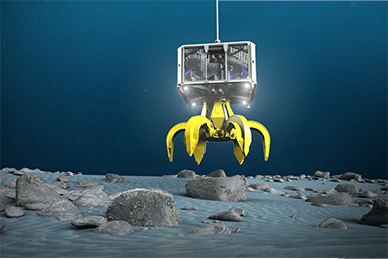

During September 2015, the FS Pegasus mobilised for a 'Boulder clearing' project in the 'offshore renewables' sector. The vessel was fitted with a 35 tonne 'A' frame over the stern and a 15 tonne 'self' tensioning winch complete with utility ROV.

The UTROV had a series of 'multi-tools' comprising of: Tine Grab, Clam Shell Grab, Shear Grab and Mass Flow Excavator. In addition to the normal lights and cameras, the UTROV was fitted with 'blue-view' thermal imaging and 'blue spider' survey tools.

The vessel was also fitted with 3 x temporary accommodation modules providing individual cabins and offices for client representatives.

The Vessel operated on the Rampion Windfarm off the South Coast of England providing diver-less boulder clearing & sea bed surveying in one pass operation.

Large underdeck capacity and excellent station-keeping capability allows us the opportunity to offer clients the services of delivering fuel and water to vessels at sea. This reduces the downtime and costs for vessels having to return to port. This service is also complimented by the delivery of ship stores as the same time. Our vessels have the capability of delivery circa 2,000 m3 of fuel oil, after a dispensation being granted by both 'Flag' and 'Class' for the carriage of MGO in our noxious liquid cargo tanks During 2015/2016 our vessels provided 'ship-to-ship' bunkering services for an international bunker trader. We obtained permission to carry an additional 900m3 of Marine Gas Oil in our noxious liquid cargo tanks, in addition to the 1,000m3 capacity of our fuel cargo tanks, resulting in a total capacity of 1900m3.

The vessel(s) were fitted with a fuel hose and reel complete with additional yokohama fenders, allowing the vessel(s) to safely hold station alongside the vessels being bunkered. The majority of vessels being bunkered were employed in 'trenching' and 'cable-laying' duties in the offshore renewal sector - allowing these vessels to continue working whilst bunkering at the same time.

We have been successful in supporting a maintenance programme of an Offshore installation. The FS Pisces was chartered for supply/support operations, but in addition was used to transfer offshore personnel required for the maintenance shutdown.

In the summer of 2015 our vessel FS Pisces (at the time non-DP) successfully supported the maintenance of an offshore floating production facility for Maersk Oil & Gas in the North Sea. The FS Pisces not only provided the normal services of a 'platform supply vessel' but was also fitted with a 'landing platform' for an Amplemann gangway.

The vessel was then engaged to provide personnel transport to the FPSO along with normal cargo duties. There was a 2nd vessel 'on location' fitted with the Amplemann gangway, this vessel would come alongside the FS Pisces and lock her DP2 fan beam system on to the reflectors located on the FS Pisces. Once the DP system was fully 'locked on' the Amplemann was deployed and personnel transferred from our vessel to the other to effect crew transfer.

We understand that this operation was the first of its kind in the North Sea.

"Fletcher's flexible and innovative approach to business and the professionalism of their crew has played an important role in helping us deliver a safe, reliable and cost-effective service to our clients. We look forward to building on this going forward as we continue to seek new and exciting opportunities in an exceptionally competitive marketplace."

Oilchart, 2016

"[We would] like to thank you and the rest of the crew on the FS Aberdour for your assistance, positive attitude and total flexibility during the last 5/6 weeks since we started this Project. The communication has been invaluable with all the challenges that have faced us. Thank you very much for your assistance, you're all a credit to your team on-board the FS Aberdour and also Fletcher Group."

Centrica, June 2017

"It was a pleasure to work with all of you, especially when the project is completed without any operation issue on the fluids / cement / waste management side. It was a great success to complete this."

Perenco, August 2017

"I cannot thank you enough for the work that you have done for us, all credit to you and your crew. I will be passing back some very positive comments. On behalf of both the Standard Princess and her crew and also the Standard Supplier, I appreciate all your help."

Centrica, November 2017